Key Insights Gained from SEM and EDS Analysis:

• Coating Thickness: SEM measures the coating's thickness with high precision, whether it's a thin film or a thick layer.

• Surface Morphology: SEM unveils surface topography, including roughness, porosity, and defects that can affect performance.

• Elemental Composition: EDS provides detailed information about the elemental composition of the coating, detecting impurities or variations.

• Elemental Mapping: EDS maps the spatial distribution of elements within the coating, offering insights into variations and potential issues.

Applications of SEM and EDS Analysis of Coatings:

•Materials Science: Investigating the microstructure and properties of protective coatings on metals, ceramics, and polymers.

• Quality Control: Ensuring the integrity and quality of coatings in industries like automotive, aerospace, and electronics.

• Corrosion Protection: Assessing the effectiveness of corrosion-resistant coatings in harsh environments.

• Surface Engineering: Evaluating engineered coatings for wear resistance, lubrication, or thermal insulation.

• Research and Development: Investigating the performance of innovative coatings and exploring new materials for future applications.

Benefits of SEM and EDS Analysis:

• High Resolution: SEM offers exceptional magnification, revealing fine details and defects in coatings.

• Quantitative Data: SEM and EDS provide quantitative information on thickness, surface roughness, and elemental composition.

• Non-Destructive: Coatings can be analyzed without altering their structure or properties.

• Problem Solving: SEM and EDS help identify the root causes of coating failures, enabling corrective actions.

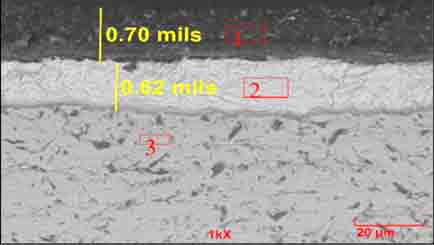

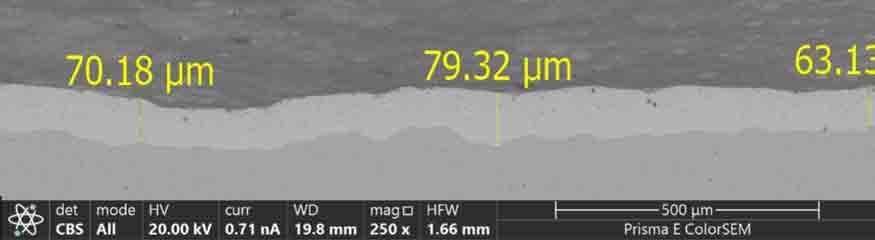

2 layers of coating, zinc layer and powder coating layer over carbon steel

SEM BSE (Backscattered Electrons) Image of Galvanic (Zinc) Coating Averaging 70.8MM

SEM/EDS For Coating Analysis

The material layering and composition can be charaterized and measured. Quality or defects can be analyzed with the SEM. (BSEs are high-energy electrons used to obtain high-resolution images that show the distribution of various elements that make up a sample.)

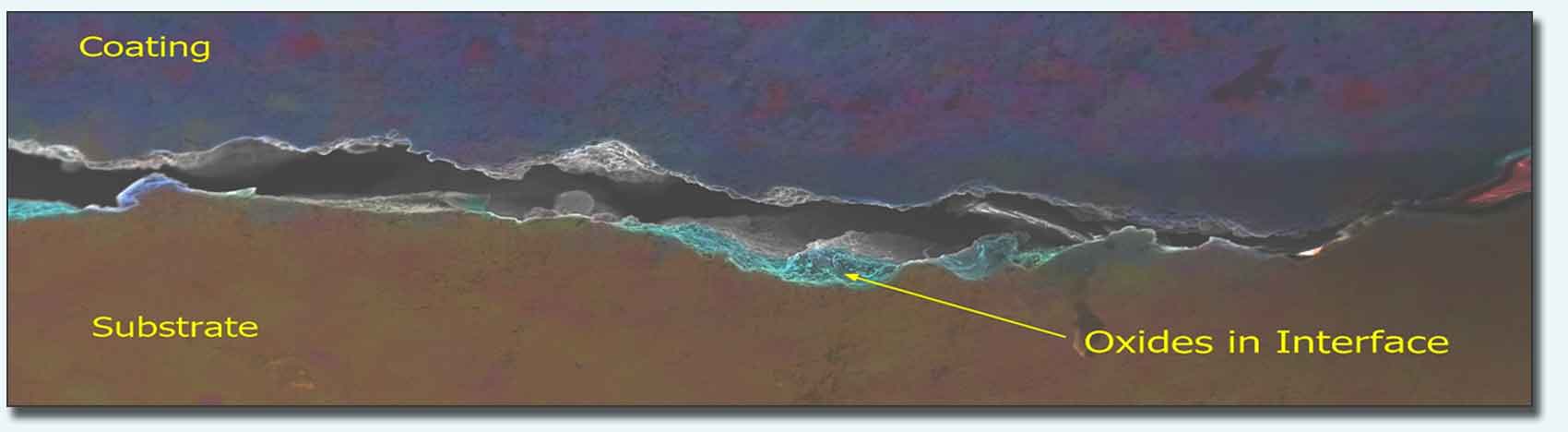

Delamination Defect

SEM/EDS Element Mapping - Delamination of Protective Coating

Delamination

ColorSEM image of a delaminated area shows a high concentration of Titanium between the layers.

Coatings Analysis

SEM and EDS analysis of coatings is a game-changer in uncovering the hidden characteristics of surface layers. Their ability to reveal coating thickness, surface morphology, and elemental composition plays a pivotal role in quality control, research, and development across various industries. As coatings continue to enhance the durability and performance of materials, SEM and EDS remain indispensable tools for diving beneath the surface and solving coating-related challenges.