Materials Analysis with ColorSEM

The ColorSEM is a very powerful microsope with magnification up to 100,000K and can detect materials from Berilum to plutonium. The It is essential in failure analysis or fractography, particle analysis, contamination analysis, corrosion analysis, research, and reverse engineering. microstructural abnormalities, grain structure, phase distribution, are often used to determine the mode and mechanism of failure.

Exotic Materials

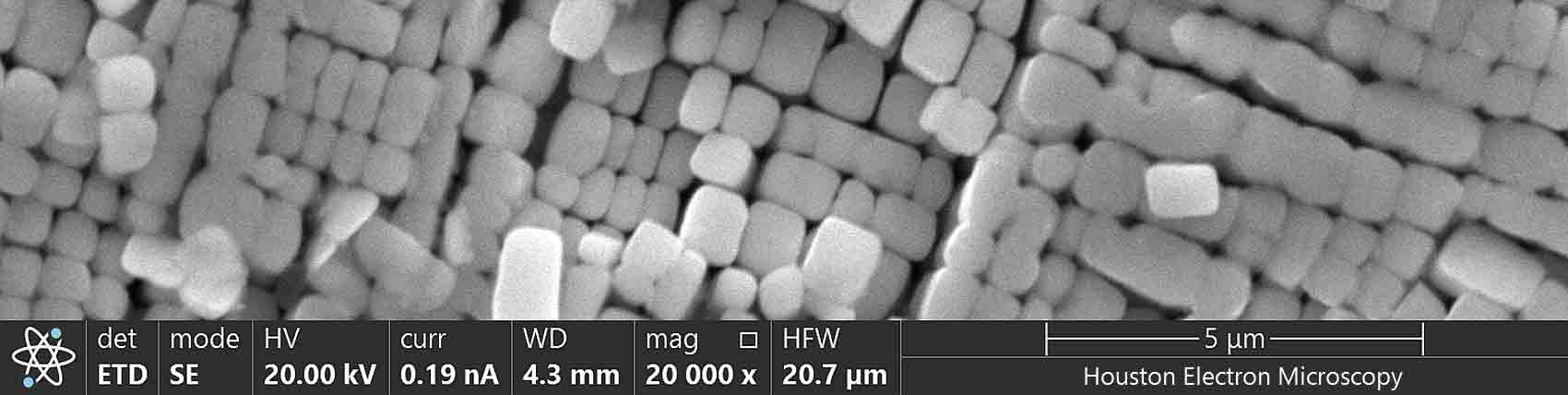

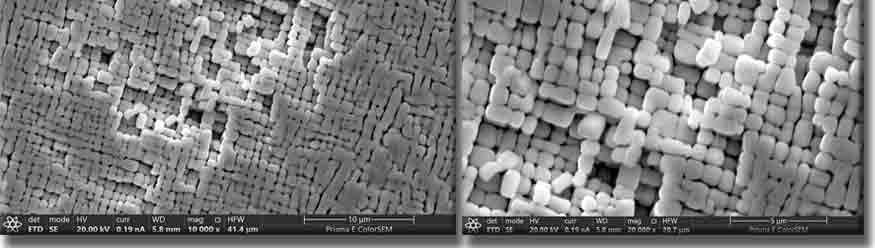

Exotic Materials are high-performance alloys of stainless steel, aluminum, nickel, titanium, magnesium, and copper. The SEM magnification and EDS can be used for the analysis of these type of alloys and other various alloy, composites, and nanocomposites. We can analyze the charachteristics of the surface morphology such as the smoothnes or roughness, homogeneity, distribution and dispersion of nanomaterials in the polymer matrix.

Low Magnification of a Titanium Component

SEM magnification at 10K and 20K

SEM Analysis of Component

Different magnifications of the titanium component show the distribution and alignement of titanium parts.

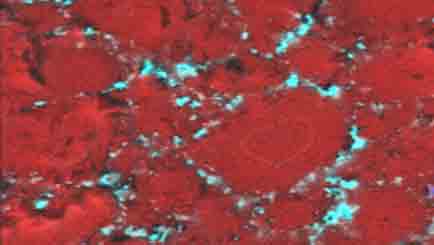

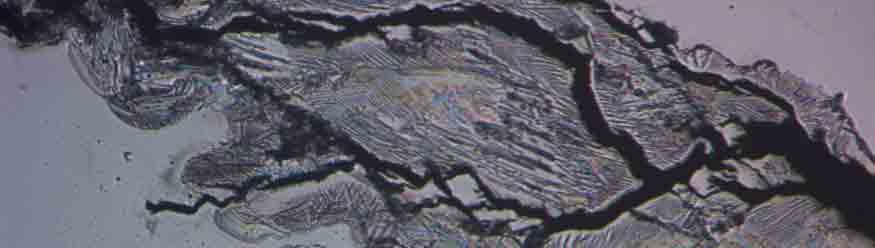

Analysis of Pores or gaps in PDC

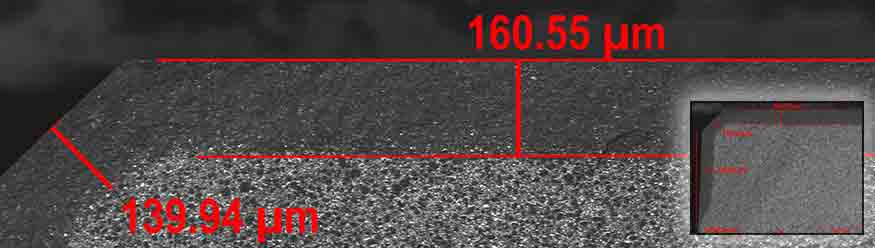

PDC - Leach Depth Measurement

PDC Analysis and Leach Depth

Measurements of the diamond leach at the micron level can be done with the Scanning Electron Microscope.

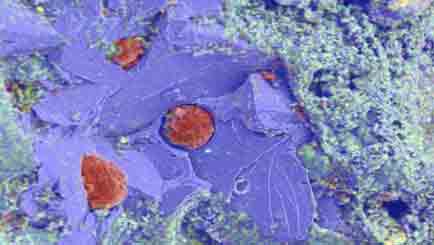

Cast Iron

What is this? It looks cool!

Failure Analysis of Metals and Alloys

cleavage planes indicate brittle fracture in ductile cast iron.

• Type I: Sulfide Inclusions

• Type II: Oxide Inclusions

EDS and SEM Topography of Alloy

SEM/EDS of metals

QC of Materials

Summary

SEM/EDS, offer a powerful means to understand the elemental composition of metals and alloys, aiding in both research and quality control applications. When witnessing of analysis is required, remote viewing is avaible so that you can observe the analysis from the comfort of you office or home office.